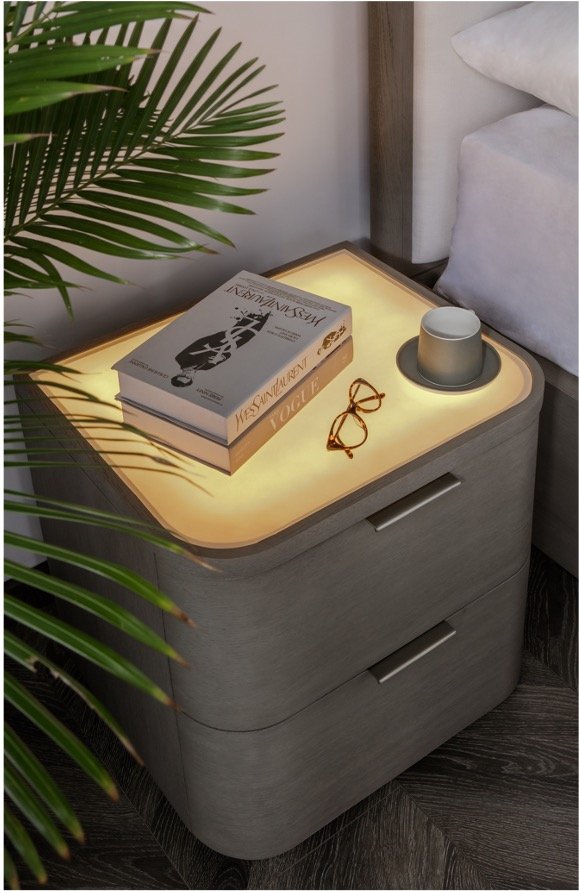

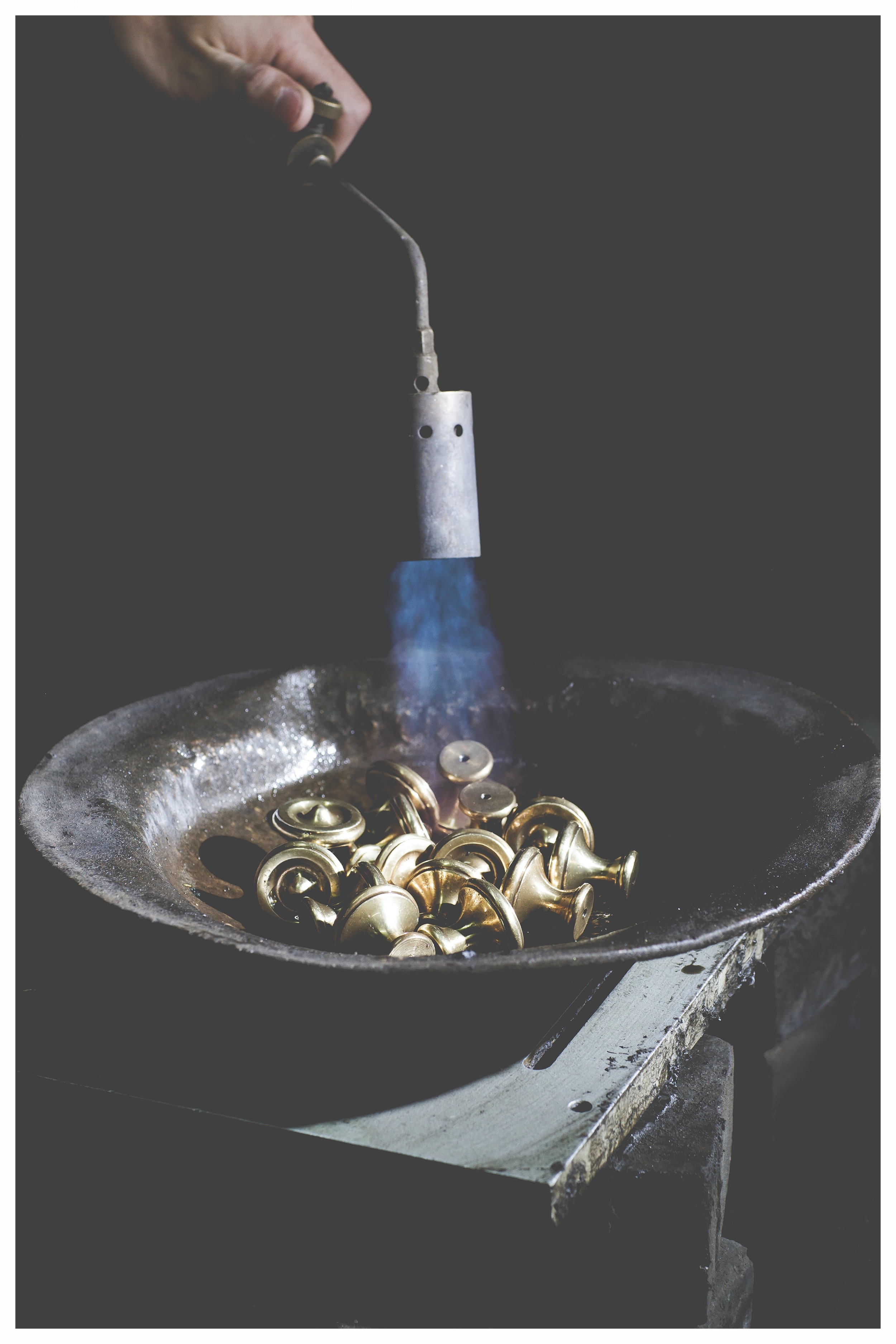

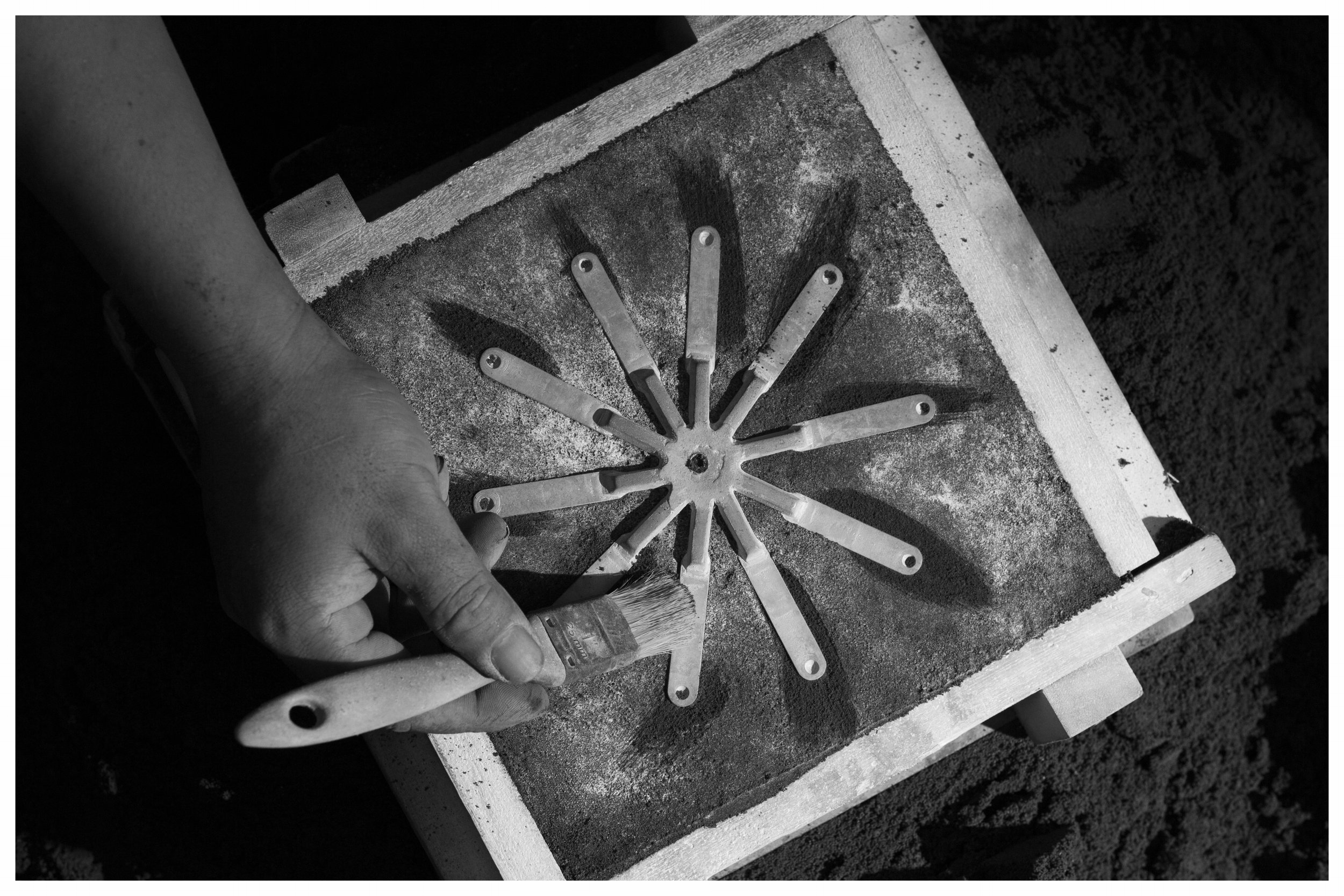

OUR FACILITIES

From our base in Thanh Phuoc, Vietnam, the Rochdale Spears Company operates several state-of-the-art proprietary manufacturing facilities. All our facilities are equipped with cutting-edge machinery such as Point-to-Point and Computer Numeric Controlled equipment, humidity control divisions and advanced spray instruments, ensuring the highest quality standards are maintained. We work with intention to reduce our environmental impact, reinforced by sustainable practices across our value chain.

Rochdale Spears has two manufacturing facilities

Case Goods & Upholstery

Our Case Goods facility, completed in 2016, covers over 800,000 square-feet, and is one of the largest purpose-built furniture manufacturing facilities of its kind in Vietnam.

Our state of the art Upholstery facility, completed in 2021, spans more than 220,000 square-feet, and houses all of our upholstery process under one roof. This facility has significantly increased our efficiencies, and more than doubled our output capacity.